Portfolio

At Fundament, we take pride in delivering innovative and practical solutions that stand the test of time...

Fencing & Gate Structural Design — Education Sector

Location: Cobblebank, VIC

Project Type: Custom Fencing & Gate Systems — Structural Certification & Compliance

Project Overview

Fundament was engaged to deliver complete structural verification and certification for a range of fencing and gate systems forming the perimeter of a new educational facility in Cobblebank. The scope included timber batten fencing, palisade-style steel barriers, and automated sliding gates, all requiring compliance with wind loading, corrosion protection, and foundation performance standards.

Working closely with CTA Metalworks and ADCO, our engineering team reviewed and certified the fabrication drawings to ensure every system achieved structural adequacy and safety in accordance with Australian Standards.

Key Challenges

- Multiple Fence Systems: Over six custom configurations, each featuring unique materials, geometries, and connection details.

- Wind Load Compliance: Designs were checked to meet AS1170.2 for non-cyclonic conditions.

- Foundation Design: Footing systems were reviewed for soil bearing and overturning performance.

- Architectural Coordination: Structures had to complement the school’s modern design using timber, steel, and perforated metal.

- Automated Gate Verification: Gate frames, track supports, and motor footings were engineered for static and operational safety.

Our Solution

- Delivered comprehensive structural assessments across all fence and gate types.

- Verified foundation integrity and durability against site-specific conditions.

- Ensured material compliance with AS4506 for long-term corrosion protection.

- Provided full certification of shop drawings covering:

- Timber Batten Fence

- Palisade Panels

- Palisade Panels with Perforated Sheet Backing

- Automated Sliding Gates

- Maintained continuous coordination with the builder and fabricator to align engineering requirements with aesthetic and site expectations.

Outcome & Benefits

✔ Structural certification issued for all fencing and gate systems

✔ Compliance with Australian standards

✔ Strong alignment between design, safety, and visual intent

✔ Reliable long-term performance and durability

✔ Streamlined project delivery through collaboration

Short Description:

Fundament provided full structural certification for fencing and gate systems at Cobblebank Secondary School, ensuring compliance with AS1170.2 and AS4100 while maintaining aesthetic and safety standards.

Server Room Structural Design & Compliance Integration

Location: Victoria, Australia

Project Type: Structural Strengthening & Secure Infrastructure Design

Project Overview

Fundament was engaged to assess and strengthen the existing structural floor system of a commercial facility to support the installation of a new fire-rated server room. The project required verifying whether the existing framing could safely carry highly concentrated loads from heavy IT rack units before determining the most efficient strengthening strategy.

Following detailed structural checks, it was identified that the existing floor members required reinforcement to safely accommodate the increased loads. Fundament’s goal was to achieve compliance and performance with minimal alteration to the existing structure, ensuring cost-efficiency and limited on-site disruption.

Key Challenges

- Assessment of Existing Structure: The floor’s original design capacity was uncertain, requiring thorough verification before new loads could be introduced.

- Heavy Point Loads: Server racks imposed concentrated loads per castor, demanding local strengthening.

- Long Spans: Existing spans of up to 7 m increased deflection and vibration risk under high equipment weight.

- Minimal Intervention Objective: Strengthening had to be achieved with the least amount of modification, maintaining existing services and finishes wherever possible.

- Compliance & Coordination: The design needed to meet AS1170 and AS4100 while integrating with fire, HVAC, electrical, and IT infrastructure.

Our Solution

Fundament developed a performance-based strengthening plan that preserved most of the original structure while ensuring full compliance and reliability:

- Structural Evaluation: Conducted detailed assessments of member capacity, deflection limits, and connection adequacy.

- Targeted Strengthening: Designed selective reinforcement of key framing zones instead of full floor replacement.

- Retrofit Options: Proposed three engineering pathways to allow flexible construction sequencing:

- Reinforced joist systems with continuous strongbacks for stiffness.

- Load-bearing partition walls to reduce effective span.

- Localised steel beam-and-column framing for concentrated loads.

- Compliance Integration: All solutions aligned with SSR (Standard Server Room) and BCSR (Business-Critical Server Room) standards, maintaining both structural and operational resilience.

Outcome & Benefits

✔ Existing floor system strengthened and certified to safely support high-density IT equipment

✔ Minimal modifications achieved despite long spans and heavy loads

✔ Full compliance with Australian standards

✔ Seamless integration with mechanical, electrical, and fire systems

✔ Reduced construction time and operational disruption

Short Description

Fundament assessed and strengthened an existing floor structure in Victoria to support a new server room, achieving AS1170 compliance with minimal modifications and disruption.

Sargood Street Residential Alteration & Addition

Location: Victoria, Australia

Project Type: Structural Engineering for Residential Renovation & Extension

Project Overview

Fundament was engaged to provide structural engineering design and certification for a residential alteration and addition project involving a rear extension and roof modifications. The works included a new meals area constructed on a subfloor system, roof framing adjustments for skylights and louvre openings, and integration of new structural elements within the existing building fabric.

The objective was to deliver a structurally sound and seamlessly integrated extension that aligned with the architectural vision while fully complying with the relevant Australian Standards.

Key Challenges

- Roof Modification Constraints: Skylight and louvre openings required careful structural detailing to maintain roof stability and load paths.

- Footing & Subfloor Integration: The new extension demanded proper footing and subfloor design to ensure adequate support, drainage, and ventilation.

- Wall and Beam Coordination: New openings within existing walls required precise beam sizing and connection detailing to integrate with timber framing.

- Existing Conditions: Structural solutions had to respect existing geometry and construction tolerances while ensuring performance.

- Standards Compliance: Design and documentation were completed in accordance with AS1684, AS2870, and AS3600.

Our Solution

Fundament developed a practical and compliant structural design that balanced buildability, cost efficiency, and architectural intent:

- Engineered subfloor footings, bearers, and joist layouts for the new meals area extension.

- Designed roof framing layouts accommodating skylights and ventilation openings while maintaining load continuity.

- Provided beam sizing, bracing, and connection details tailored to site conditions and framing types.

- Delivered clear construction documentation optimised for sequencing and builder implementation.

- Conducted coordination reviews with the builder to ensure smooth integration during site works.

Outcome & Benefits

✔ Structurally reliable and architecturally integrated home extension

✔ Full compliance with Australian standards

✔ Efficient framing and footing system for long-term durability

✔ Design aligned with existing conditions and site constraints

✔ Streamlined construction through clear documentation and coordination

Short Description:

Fundament provided structural engineering design and certification for a residential renovation and extension in Victoria, ensuring AS1684 and AS2870 compliance with seamless integration of new roof and subfloor systems.

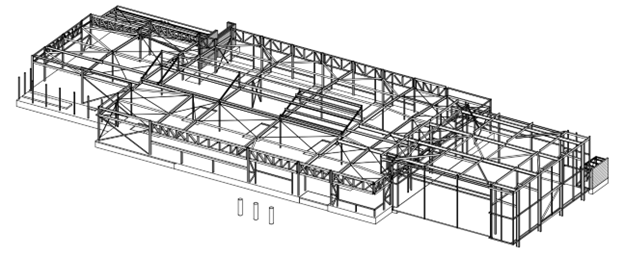

Fire Station Redevelopment – Demolition, Truss Reinforcement & Temporary Works

Location: Broadmeadows, VIC

Project Type: Demolition Engineering, Temporary Works & Truss Support

Project Overview

Fundament was engaged to deliver comprehensive structural engineering services for the demolition and redevelopment of an operational fire station in Broadmeadows. The project required detailed assessment of the existing roof truss system, design of temporary structural supports, and development of a certified demolition methodology that ensured stability and safety during the removal of load-bearing elements.

All works were undertaken in accordance with the Safe Work Australia Demolition Code of Practice (2012) and coordinated closely with the builder to maintain operational safety and regulatory compliance throughout the process.

Key Challenges

- Truss Stability: The existing steel trusses needed to remain stable while surrounding roof and wall structures were dismantled.

- Temporary Support Design: Required an engineered and certifiable propping system to carry and redistribute roof loads safely.

- Complex Site Conditions: Limited access, service disconnections, and hazardous material clearances required careful sequencing.

- Safety Management: Ongoing fire station operations demanded strict risk management and coordination with on-site teams.

- Regulatory Compliance: The design needed to satisfy demolition, temporary works, and structural safety requirements simultaneously.

Our Solution

Fundament provided an integrated structural and safety-driven engineering package that addressed both demolition and re-staging needs:

- Strengthened the existing truss system with welded steel reinforcement to maintain stability during demolition.

- Designed a certified temporary propping arrangement using engineered beam and prop systems for safe load transfer.

- Verified the slab and footing capacities to sustain both temporary and residual loads.

- Prepared detailed drawings, risk analyses, and staging methodologies for contractor implementation.

- Reviewed and endorsed the contractor’s Safe Work Method Statements (SWMS) to align with regulatory expectations.

- Provided continuous engineering oversight throughout demolition to manage risk and ensure safe progression.

Outcome & Benefits

✔ Controlled demolition with roof trusses safely retained and supported

✔ Certified and buildable temporary support system

✔ Compliance with Safe Work Australia Demolition Code (2012)

✔ Minimized safety risk and structural uncertainty

✔ Clear engineering documentation for seamless transition to reconstruction phase

Short Description:

Fundament provided demolition engineering and temporary works design for the Broadmeadows Fire Station redevelopment, ensuring truss stability and full compliance with the Safe Work Australia Demolition Code.

Factory Structural Redesign & Beam Assessment – Replacement of Three Industrial Tanks

Location: Springvale, VIC

Project Type: Structural Assessment & Redesign in Operational Industrial Facility

Project Overview

Fundament was engaged to provide structural assessment, redesign, and engineering certification within an operational manufacturing facility undergoing the replacement of three industrial tanks. The works required a careful balance of structural integrity, operational continuity, and safety.

The project scope included the removal and modification of existing beams, verification of an elevated platform supporting a moving pallet system, and design of new structural framing and footings around the tank areas.

Key Challenges

- Beam Modification & Assessment: Existing steel beams near the tank zones had to be safely cut, evaluated, and redesigned without compromising the surrounding structure.

- Platform Verification: The elevated platform supporting moving pallets required load capacity checks under revised industrial conditions.

- Structural Integration: New beams, supports, and footings had to blend seamlessly with retained elements within tight clearances.

- Operational Constraints: All engineering and construction activities needed to proceed without disrupting ongoing factory operations.

- Code Compliance: Designs were required to meet relevant Australian Standards for structural safety in industrial environments.

Our Solution

Fundament delivered a comprehensive and coordinated engineering response tailored to the active site conditions:

- Conducted structural assessments of existing beams and the pallet platform under updated load requirements.

- Engineered safe beam-cutting and modification procedures, ensuring local stability during removal works.

- Designed new steel framing systems and custom footing arrangements for all three tank replacement zones.

- Detailed precise connection interfaces between new and existing structural members.

- Developed sequencing and staging documentation to minimise on-site interruption.

- Provided construction-phase inspections and engineering support to maintain compliance and safety throughout installation.

Outcome & Benefits

✔ Successful integration of new tank structures within an operational factory

✔ Verified load capacity and stability of existing and new framing

✔ Zero disruption to production during structural works

✔ Optimised design solutions despite limited access and space

✔ Full compliance with Australian Standards and factory safety requirements

Short Description:

Fundament completed structural redesign and assessment for an operational factory in Springvale, delivering safe beam modifications and new framing to support the replacement of three industrial tanks with zero production downtime.

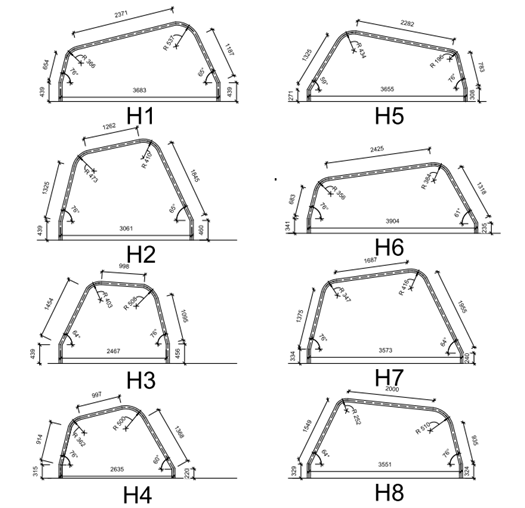

Structural Design Review – Outdoor Steel Play Structure

Location: Winchelsea, VIC

Project Type: Structural Assessment of Steel Play Equipment

Project Overview

Fundament was engaged to undertake a structural design review of a custom-fabricated outdoor steel play structure designed for public use in a community recreation area. The scope involved detailed assessment of the steel framing system, connection details, and foundation design to ensure the structure achieved the highest standards of safety, durability, and long-term compliance for public installations.

The review focused on load capacity verification, corrosion protection, and connection integrity, ensuring that the structure was safe for children and fully aligned with the architectural and fabrication intent.

Key Challenges

- Public Safety Standards: The structure had to meet stringent safety requirements suitable for children’s play environments.

- Corrosion Protection: All steel elements required durable, weather-resistant finishes for long-term outdoor exposure.

- Connection Detailing: Welds, bolts, and base plates required thorough structural verification for fatigue and stability.

- Foundation Adequacy: Lightweight tubular columns needed reliable anchorage and footing performance.

- Design Coordination: The engineering review had to integrate seamlessly with architectural drawings and manufacturer documentation.

Our Solution

Fundament delivered a comprehensive engineering assessment and certification package, ensuring safety, durability, and design compliance:

- Reviewed steel frame geometry and load paths in accordance with AS4100 and AS1170 requirements.

- Verified bolted and welded connections, including chemical anchor suitability and embedment.

- Confirmed base plate and footing configurations to ensure adequate structural capacity.

- Recommended protective coating systems to enhance corrosion resistance and service life.

- Issued engineering certification confirming the structure’s compliance and suitability for public use.

Outcome & Benefits

✔ Verified structural safety and stability for community installation

✔ Full compliance with Australian standards

✔ Long-term durability through effective material and coating selection

✔ Seamless coordination between engineering, architectural, and fabrication teams

✔ Final certification enabling safe, timely installation for public enjoyment

Short Description:

Fundament reviewed and certified an outdoor steel play structure in Winchelsea, ensuring compliance with Australian standards for safe, durable, and child-friendly public use.

Aluminium Balustrade System – Cambridge Street Apartments

Location: Collingwood, VIC

Project Type: Structural Design & Compliance Certification for Balustrade System

Project Overview

Fundament was engaged to provide structural engineering design and compliance certification for the aluminium balustrade systems at a multi-level residential development in Collingwood. The scope covered the design, detailing, and certification of modular balustrade units installed across five apartment levels and the basement carpark.

The engineering work ensured full compliance with NCC 2019 Volume 1 (Amendment 1) and the relevant Australian Standards, delivering a robust and durable balustrade system aligned with the project’s architectural design intent by Warren and Mahoney Architects.

Key Challenges

- Multi-Level Installation: Balustrades were required across multiple storeys with variations between apartment levels and the basement carpark, demanding tailored fixing and structural detailing.

- NCC & AS Compliance: The design had to meet stringent loading, durability, and fixing requirements under the National Construction Code and Australian Standards.

- Architectural Coordination: Structural detailing needed to align seamlessly with architectural documentation and aesthetic expectations.

- Regulatory Certification: As prescribed building work, the design required a Certificate of Compliance under Section 238(1)(a) of the Building Act 1993 and Regulation 126 of the Building Regulations 2018.

Our Solution

Fundament’s engineering team carried out a comprehensive structural design and documentation process to ensure compliance, constructability, and aesthetic integration:

- Completed structural design and verification for all aluminium balustrade units across five levels.

- Developed fixing and embedment details into concrete slabs and hobs to meet load transfer requirements.

- Ensured full compliance with NCC 2019 Volume 1 (Amendment 1) and applicable Australian Standards, including AS1288, AS1170, AS3600, and AS4100.

- Prepared and issued a Certificate of Compliance for the proposed building work under the Building Act 1993.

- Coordinated closely with Gardner Group and Warren and Mahoney Architects to align structural deliverables with architectural documentation and site installation.

Outcome & Benefits

✔ Certificate of Compliance issued under Building Act 1993 – Section 238(1)(a)

✔ Full structural compliance with NCC 2019 Volume 1 (Amendment 1)

✔ Robust and code-compliant fixing methodology across all balustrade units

✔ Modular design ensured efficient installation and consistent fabrication quality

✔ Zero remedial work required post-installation due to precise documentation and coordination

Short Description:

Fundament provided structural design and compliance certification for aluminium balustrade systems at a Collingwood apartment development, ensuring NCC 2019 and Building Act 1993 compliance with seamless architectural coordination.

Custom Aluminium Shelf System – Adamson Street Apartments

Location: Brighton, VIC

Project Type: Interior Metalwork Design & Fixing Coordination

Project Overview

Fundament was engaged to support the design coordination and installation methodology for custom aluminium shelving systems across multiple apartments within the Adamson Street residential development.

The shelving was fabricated offshore, requiring highly accurate documentation and coordination to ensure precise installation upon delivery — without the opportunity for site remeasurement. The project demanded meticulous structural detailing, coordination with architectural layouts, and fixing solutions suitable for internal blockwork conditions.

Key Challenges

- No On-Site Measure: The shelving was fabricated overseas, meaning all drawings and dimensions had to be finalised before installation, with no allowance for site verification.

- Complex Fixing Conditions: Anchoring into blockwork required structurally sound fixing design, respecting minimal edge distances and embedment depths.

- Anchor Clash Risk: Flat bar braces risked interference with chemical anchor plates unless precisely coordinated.

- Visual Alignment: Architectural intent required perfect symmetry and level consistency across all apartment units.

Our Solution

Fundament’s engineering team delivered a comprehensive coordination and verification process, ensuring precision fabrication and seamless installation:

- Confirmed all critical dimensions and tolerances before offshore fabrication.

- Specified chemical anchor type, embedment depth, and spacing suitable for blockwork conditions.

- Adjusted flat bar positioning to prevent interference with anchor plates.

- Provided installation guidance including caulking details, panel jointing, and field adjustment allowances.

- Ensured documentation consistency across all apartment units for repeatable accuracy.

Outcome & Benefits

✔ Offshore fabrication achieved with zero remeasurement required

✔ Accurate, clean installation across all apartment units

✔ Structurally robust and visually aligned shelving system

✔ Eliminated clash risks through proactive detailing

✔ Maintained architectural integrity with no on-site rework

✔ Documentation scalable for future project replication

Meta Description:

Fundament provided design coordination and structural detailing for offshore-fabricated aluminium shelving systems at the Adamson Street Apartments in Brighton, ensuring precise installation and architectural alignment without on-site remeasurement.

Formwork Inspection & Structural Verification – VCC Epsom

Location: Epsom, VIC

Project Type: Formwork Inspection & Structural Assessment in Commercial Project

Project Overview

Fundament was engaged to perform a structural inspection and verification of a formwork system designed to support a 250 mm reinforced concrete slab during casting and curing at a commercial development in Epsom.

Working in collaboration with 4Site Design Group, the inspection involved a detailed on-site assessment of joists, bearers, sheeting, and vertical props to confirm structural adequacy, span compliance, and safety in accordance with relevant Australian Standards and site requirements.

Key Challenges

- Span Compliance: Verification of bearer and joist spans to ensure they could safely support slab loads during pouring and curing.

- Ply Support Adequacy: Assessment of plywood strength and stiffness over closely spaced joists.

- Prop Stability: Evaluation of Acrow prop positioning and stability at height to prevent displacement under load.

- Time Constraints: Completion of inspection and certification within the tight construction schedule before the slab pour.

Our Solution

Fundament’s structural engineering team carried out a comprehensive field assessment supported by detailed calculations and formwork documentation review:

- Verified bearer and joist spans were within allowable limits for the specified timber sizes.

- Confirmed plywood grade and thickness provided adequate load support between joists.

- Evaluated prop height and alignment to ensure safe vertical load transfer.

- Issued a no-objection report, confirming the system’s adequacy for the scheduled concrete pour.

- Recommended real-time monitoring during pouring to detect early signs of deflection or movement.

Outcome & Benefits

✔ Formwork system verified as structurally adequate and safe

✔ Slab pour completed without delay or incident

✔ Full compliance with Australian construction and safety standards

✔ Enhanced contractor confidence through independent engineering review

✔ Mitigation of on-site risks and assurance of quality workmanship

Short description:

Fundament conducted formwork inspection and structural verification for a 250 mm concrete slab at a commercial site in Epsom, confirming compliance and safety for the scheduled pour.

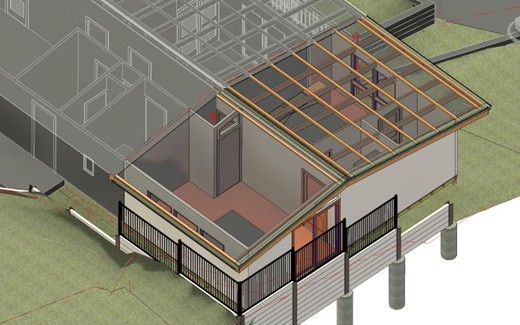

Structural Engineering & Certification for Custom Glazed Hipped Roof Canopy – 198 Osborne Street

Location: Williamstown, VIC

Project Type: Structural Design & Certification for Architecturally Integrated Roof Canopy

Project Overview

Fundament was appointed to deliver the structural design, detailing, and certification for a bespoke glazed hipped roof canopy forming part of a high-end retail frontage enhancement in Williamstown.

The project involved a fully welded galvanized RHS/SHS steel frame designed to support overhead double-glazed panels, requiring precise coordination between structural geometry, glazing system tolerances, and architectural finishes. The canopy’s complex hipped form demanded accurate 3D modelling and integration with proprietary EC glazing extrusions while maintaining watertight performance and aesthetic quality.

Key Challenges

- Geometric Complexity: The canopy’s hipped configuration required exact 3D alignment across ridge, hip, jack, and common rafters while supporting sloped glass panels under self-weight and environmental loads.

- Overhead Glazing Compliance: All framing and fixings were designed in full accordance with AS1288–2021, Section 6, ensuring safety and compliance for sloped overhead glazing.

- Material Integration: The steel frame needed to securely anchor into existing timber upstands and coordinate with the glazing extrusion system without compromising waterproofing.

- Detailed Compliance: Every component — welds, bolts, and finishes — had to comply with AS4100, AS1554, and AS1214, with a focus on corrosion resistance for exposed conditions.

Our Solution

Fundament’s engineers developed a reinforcement and framing strategy that maintained the architectural elegance of the canopy while achieving full structural and safety compliance:

- Designed and certified a fully welded DuraGal RHS/SHS steel frame for strength, precision, and longevity.

- Developed anchorage and perimeter plate details using high-strength mechanical fixings into existing timber framing.

- Optimised framing geometry for perfect compatibility with EC glazing profiles and controlled thermal expansion.

- Ensured compliance with all relevant AS/NZS standards governing steelwork and overhead glazing systems.

- Coordinated closely with the builder, glazing supplier, and architectural team to ensure alignment between structure, glazing, and finish.

Outcome & Benefits

✔ Precision-engineered structural system aligned with architectural design intent

✔ Full compliance with AS4100, AS1554, AS1214, and AS1288–2021

✔ Seamless integration between glazing, structural, and architectural components

✔ Durable, low-maintenance solution ensuring long-term performance

✔ Enhanced daylight and aesthetic value at the building’s entry façade

Canopy Structural Design – Saint Moritz Development

Location: St Kilda, VIC

Project Type: Structural Design & Certification for Architectural Canopy

Project Overview

Fundament was engaged to deliver the structural design and certification for a custom steel canopy at the Saint Moritz residential development in St Kilda. The project required precise structural design that maintained architectural alignment, ensured safety, and met all relevant Australian Standards.

The scope covered the design of framing members, baseplates, and anchorage systems, as well as the preparation of construction documentation and certification for approval. The canopy had to integrate seamlessly with the façade and glazing system while allowing for efficient on-site installation within a high-traffic construction environment.

Key Challenges

- Architectural Coordination: Achieving a seamless interface between the canopy, façade, and glazing elements.

- Anchorage Design: All supports relied on ChemSet anchors into existing slabs, requiring precise control of embedment depth and edge distances.

- Buildability Constraints: The structure needed to allow quick, safe installation with minimal disruption to ongoing works.

- Standards Compliance: Full adherence to AS/NZS structural design codes and local engineering requirements was essential.

Our Solution

Fundament’s engineering team delivered a comprehensive structural solution balancing strength, precision, and aesthetic intent:

- Designed RHS and SHS framing members optimised for stiffness, appearance, and constructability.

- Engineered baseplates and anchorage systems with detailed edge distance and embedment verification.

- Produced fully documented construction drawings and issued formal engineering certification.

- Maintained close coordination with the architect and builder to ensure visual alignment and ease of installation

Outcome & Benefits

✔ Structurally compliant canopy certified to AS/NZS design standards

✔ Seamless integration with façade and glazing systems

✔ Design enabled rapid, efficient installation with zero rework

✔ Collaborative approach ensured aesthetic precision and project efficiency

Ararat Double-Storey Alterations & Additions Structural Design

Location: Ararat, Victoria, Melbourne

Project Type: Structural Design for Alterations & Additions to a Double-Storey Building

Project Scope

Fundament was engaged to provide the structural design for alterations and additions to a double-storey building in Ararat, Melbourne. The project involved removing internal walls in the basement, modifying the first-floor layout, and designing additions supported by a Bondeck slab, along with balcony extensions over the ground floor.

Challenges

- Basement Wall Removal: Assessing the impact on structural stability and designing alternative load paths.

- First-Floor Additions: Ensuring the new layout and extensions were structurally sound.

- Bondeck Slab Design: The additional slab weight needed to be properly supported by the existing structure.

- Existing Footing Evaluation: Checking whether the footings could handle increased loads from the new additions.

- Non-Standard Column Sections: The client requested the use of non-standard steel sections, requiring detailed capacity verification.

- Temporary Propping: Considering safe propping methods during slab construction to prevent structural instability.

Our Solution

Our structural engineers developed a reinforcement strategy that ensured the integrity of the modified structure while optimizing material use. Key solutions included:

✅Basement Structural Reinforcement: Designed load transfer solutions to compensate for removed walls.

✅Optimized Bondeck Slab Design: Ensured the slab weight was adequately distributed through the existing structure.

✅Existing Footing Assessment & Strengthening: Verified footing capacity and proposed reinforcement where necessary.

✅Capacity Verification for Non-Standard Columns: Conducted structural analysis to confirm suitability for load-bearing applications.

✅Safe Temporary Propping Strategy: Developed a temporary propping plan to support the structure during construction.

✅Compliance with Australian Standards: Ensured adherence to AS 3600 (Concrete Structures) and AS 4100 (Steel Structures) for safety and durability.

Outcome & Benefits

✔Safe & Efficient Basement Modifications: Load redistribution maintained structural stability after wall removal.

✔Well-Supported First-Floor Additions: The Bondeck slab and balcony extensions were properly reinforced for long-term performance.

✔Optimized Use of Non-Standard Sections: Engineering analysis ensured structural adequacy of client-specified columns.

✔Secure Construction Process: Implemented temporary propping solutions to maintain safety during construction.

✔Regulatory Compliance: Fully met Australian structural engineering standards.

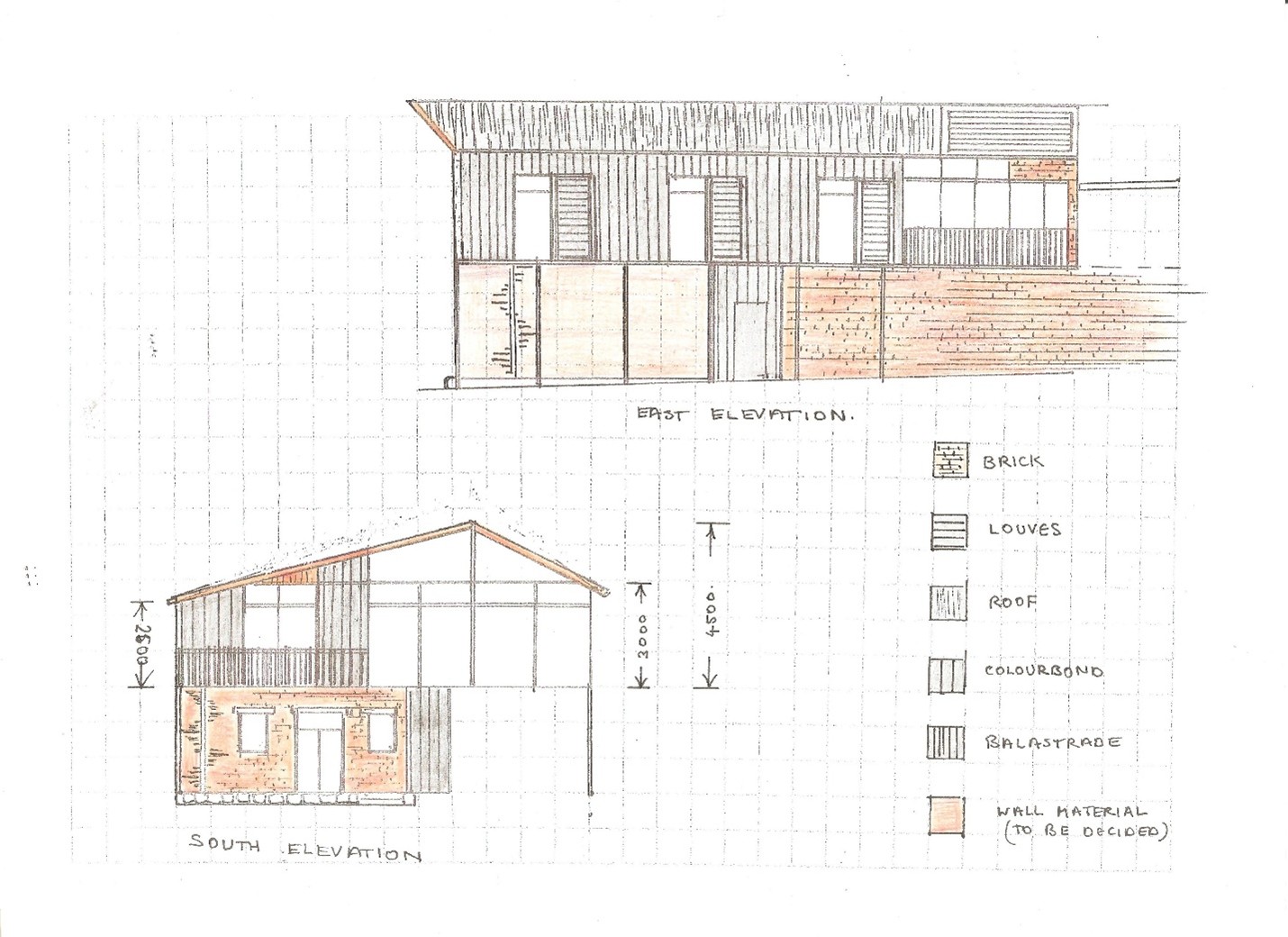

Tecoma Alterations & Additions Structural Design

Location: Tecoma, Victoria, Melbourne

Project Type: Structural Design for Alterations & Additions to an Existing Building

Project Scope

Fundament was engaged to provide the structural design for alterations and additions to an existing residential building in Tecoma, Melbourne. The project involved modifying the roof structure while maintaining an aesthetic and open design that aligned with the client’s vision.

Challenges

- Long Roof Rafter Spans: The project included long-span rafters, which became even more challenging after removing an internal supporting wall.

- Maintaining Aesthetic Integrity: The client wanted to keep the raked ceiling and exposed rafters, meaning the rafter sizes needed to remain consistent throughout the space.

- Structural Adequacy: Ensuring the rafters remained structurally sound without increasing their depth or altering the overall appearance.

Our solution

Our structural engineers developed a reinforcement strategy that maintained the design aesthetic while ensuring structural performance. Key solutions included:

✅Strategic Blocking Between Rafters: Introduced blocking between rafters to distribute loads and reduce deflection, ensuring structural adequacy without increasing rafter size.

✅Load Path Optimization: Ensured the roof loads were effectively transferred to the supporting structure.

✅Preserved Architectural Intent: The solution maintained the open, exposed rafter design while ensuring compliance with structural safety requirements.

✅Compliance with Australian Standards: Adhered to AS 1684 (Residential Timber Framing Code) to ensure stability and durability.

Outcome & Benefits

✔Maintained the Raked Ceiling Aesthetic: The design preserved the original exposed rafter concept without increasing member sizes.

✔Structurally Sound Roof System: The reinforced rafter spans ensured long-term performance and reduced deflection.

✔Efficient & Practical Design: The blocking strategy provided structural adequacy without requiring expensive or visually intrusive modifications.

✔Regulatory Compliance: Fully met Australian structural engineering standards.

Rosebud Single-Storey Structural Design

Location: Rosebud, Victoria, Melbourne

Project Type: Full Structural Design for a Single-Storey Dwelling

Project Scope

Fundament was engaged to provide the full structural design for a single-storey residential dwelling in Rosebud, Melbourne. The project was relatively straightforward, requiring an efficient and cost-effective structural solution while ensuring compliance with Australian standards.

Challenges

- Large Roof Overhang: One section of the roof featured a significant overhang, requiring additional stability measures.

- Structural Optimization: The challenge was to reinforce the overhang without excessive material use or unnecessary structural elements.

Our Solution

Our structural engineers optimized the roof design while maintaining stability and efficiency. Key solutions included:

✅Tying Back the End Rafter & Trimmer Beams: Implemented strategic connections to enhance the structural performance of the overhang.

✅Load Path Optimization: Ensured the forces from the overhang were properly transferred to the main structure.

✅Reinforced Framing System: Used LVL beams and rafters where necessary to support the extended section.

✅Efficient & Cost-Effective Approach: Designed a stable and structurally sound solution without excessive reinforcement.

✅Compliance with Australian Standards: Ensured adherence to AS 1684 (Residential Timber Framing Code) and AS 2870 (Residential Slabs and Footings) for safety and longevity.

Outcome & Benefits

✔Structurally Stable Roof Overhang: The solution provided long-term stability while maintaining the architectural intent.

✔Optimized Structural Performance: The efficient design approach minimized material usage while ensuring integrity.

✔Cost-Effective Construction: Achieved practical and economical solutions without compromising safety.

✔Regulatory Compliance: Fully met Australian structural engineering standards.

Mt Eliza Single-Storey Structural Design

Location: Mt Eliza, Victoria, Melbourne

Project Type: Structural Design for a Single-Storey Dwelling

Project Scope

Fundament was engaged to provide the structural design for a single-storey residential dwelling on a sloped site in Mt Eliza, Melbourne. The dwelling was divided into three distinct sections, each maintaining structural integrity while incorporating different finished floor levels. The design needed to balance architectural complexity, cost efficiency, and structural adequacy while ensuring proper ventilation and compliance with Australian standards.

Challenges

- Sloped Site Constraints: Designing a structurally sound foundation and framing system to accommodate the slope.

- Varying Floor Levels: Each section had different finished floor levels, requiring careful planning to ensure stability and integration.

- Architectural Complexity: The design featured curved walls, varying wall alignments, and large spans, making efficient framing essential.

- Retaining Walls: Structural retaining walls were needed between sections to manage elevation differences.

- Cost Efficiency: Selecting construction methods that were cost-effective while maintaining structural integrity.

- Ventilation Requirements: Ensuring proper airflow and moisture management throughout the structure.

Our solution

Our structural engineers developed a customized framing and foundation system that addressed the project's unique challenges while optimizing costs. Key solutions included:

✅Site-Specific Foundation System: Designed a combination of slab-on-ground and retaining wall-supported foundations to adapt to the slope.

✅Optimized Framing for Large Spans: Used engineered timber and LVL beams to efficiently support the open spaces and architectural features.

✅Integrated Retaining Walls: Designed reinforced concrete retaining walls between sections to provide stability and elevation management.

✅Architectural Framing Solutions: Proposed framing techniques to accommodate curved walls and varying volumes without excessive costs.

✅Cost-Effective Structural Approach: Selected construction materials and methods that ensured structural adequacy while minimizing unnecessary expenses.

✅Enhanced Ventilation Strategy: Incorporated subfloor ventilation and strategic airflow pathways to promote moisture control and thermal efficiency.

✅Compliance with Australian Standards: Ensured adherence to AS 1684 (Residential Timber Framing Code) and AS 2870 (Residential Slabs and Footings) for safety and durability.

Outcome & Benefits

✔Structural Stability Across Different Levels: Successfully integrated multiple floor levels while maintaining stability and durability.

✔Preserved Architectural Aesthetic: Engineered solutions supported curved walls, varying alignments, and large spans.

✔Efficient Use of Retaining Walls: Provided structural support and terrain adaptation between sections.

✔Cost-Effective & Practical Construction: The proposed methods ensured financial efficiency without compromising structural performance.

✔Optimized Ventilation & Moisture Control: Implemented effective airflow solutions to enhance comfort and durability.

✔Regulatory Compliance: Fully met Australian structural engineering standards.

Inverloch Double-Storey Timber Framing Project

Location: Inverloch, Melbourne

Project Type: Proposed Construction of a Double-Storey Single Dwelling

Project Scope

Fundament was engaged to design the timber framing structure for a double-storey residential dwelling in Inverloch, Melbourne. The project required an efficient, cost-effective structural system that could support large spans and wide openings while maintaining stability and compliance with Australian standards.

Challenges

- High-Span Structural Requirements: The design included large open spaces that required careful load distribution

- Cost Optimization: The goal was to utilize timber framing instead of alternative high-cost structural materials

- Stability Considerations: Ensuring adequate lateral and vertical support for long spans and openings

- On-Site Construction Deviations: The as-built structure differed from the original engineering drawings, requiring a structural review

- Compliance with Australian Standards: Adhering to AS 1684 (Residential Timber Framing Code) for safety and durability

Our Solution

Our structural engineers developed a timber framing strategy that successfully addressed the challenges while optimizing costs. Key solutions included:

✅Optimized Beam and Column Placement: Ensured structural efficiency by strategically distributing loads while maintaining open spaces.

✅Reinforced Timber Framing: Used LVL (Laminated Veneer Lumber) and engineered timber beams to support high-span areas.

✅Cost-Effective Structural Design: Eliminated the need for excessive steel framing, reducing material costs while maintaining strength.

✅Bracing and Load Distribution: Integrated shear walls and bracing elements to enhance stability and wind resistance.

✅Assessment of Modified Construction: Conducted a detailed structural evaluation of the modified parts of the build.

✅Rectification Work: Developed a practical structural solution that ensured the stability of the project while minimizing unnecessary work and costs.

✅Compliance with AS 1684: Ensured the framing system met all regulatory requirements for residential timber structures.

Outcome & Benefits

✔Cost Savings Achieved: Timber framing reduced construction costs without compromising stability.

✔Efficient Structural Performance: Successfully accommodated large spans and big openings with a lightweight yet durable design.

✔Structural Integrity Restored: The rectification work guaranteed compliance and long-term structural adequacy.

✔Optimized Stability: The structure maintains long-term integrity and load distribution efficiency.

✔Regulatory Compliance: Met all Australian timber framing standards (AS 1684).

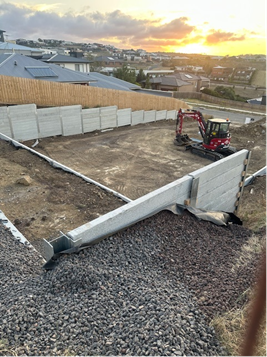

Highton Sleeper Wall Retaining Wall Project

Location: Highton, Melbourne

Project Type: Structural Retaining Wall Design

Overview

Fundament was engaged to design a tiered concrete sleeper retaining wall for a residential property in Highton, Melbourne. The retaining wall was necessary to provide structural support to sloped terrain, prevent soil erosion, and enhance land stability for future landscaping and construction purposes.

Challenges

- Soil Stability Concerns: The site had varying soil conditions that required careful assessment

- Load-Bearing Requirements: The retaining wall needed to withstand lateral soil pressure and external loads

- Drainage Considerations: Proper water management was essential to prevent hydrostatic pressure buildup behind the wall

- Local Regulations: Compliance with Australian retaining wall design standards (AS 4678) and local council requirements

Our solution

Our team of structural engineers implemented a reinforced tiered concrete sleeper retaining wall system, incorporating:

✅Engineering-Designed Retaining Wall: Calculated lateral earth pressures and designed the wall to withstand forces effectively.

✅High-Strength Sleeper Selection: Used durable, reinforced concrete sleepers for longevity and load-bearing performance.

✅Drainage System Integration: Installed weep holes and subsoil drainage to prevent water accumulation and soil expansion.

✅Structural Support Measures: Designed post embedment depths and reinforcement details to maximize stability.

✅Compliance with AS 4678: Ensured all structural elements met Australian standards for safety and durability.

Outcome & Benefits

✔Structural Stability Improved: The retaining wall effectively supports the property’s terrain, reducing erosion risks.

✔Aesthetic & Functional Design: The sleeper wall provides both visual appeal and long-term durability.

✔Enhanced Drainage & Load Performance: Engineered solutions minimize water pressure and extend the lifespan of the structure.

✔Regulatory Compliance: Successfully met all local council and AS 4678 requirements.